Skip to content

amTrinCook EKL – Sustainable Packaging Solution for Cooking Meat in the Oven

Home/amTrinCook EKL – Sustainable Packaging Solution for Cooking Meat in the Oven

amTrinCook EKL – Sustainable Packaging Solution for Cooking Meat in the Oven

We pay attention to ecology

More and more consumers are reaching for ecological packaging, contributing to the reduction of CO2 production, recyclable, biodegradable or made of processed materials, which is why food companies are looking for packaging solutions that fit in with the idea of sustainable development and circular economy.

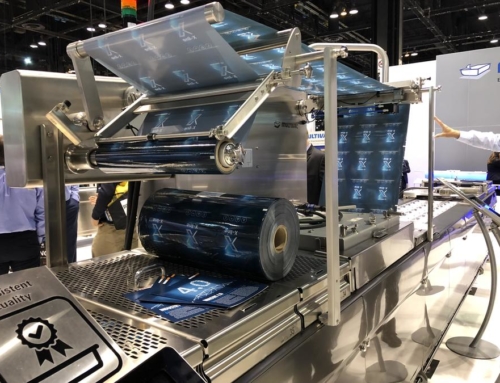

amTrinCook EKL films are barrier packaging films based on mono-materials (PET, PE or PP) for oven cooking meat – seasoned or marinated, with the addition of sauces and even vegetables – as a ready dish to be prepared in a home oven – freshness, healthy ingredients and simplicity. The amTrinCook series is an excellent alternative to films with a mixed composition, which negatively affect the pollution of the Earth with plastic – after use, they are stored or incinerated. The mono-material amTrinCook packaging film for oven cooking is a fully recyclable product, and its properties enable use in a wide temperature range from -40°C (-40°F) to 220°C (430°F). Available are top and bottom films for thermoformers, lidding films for trays, bags / pouches and films for flow-pack machines with a barrier layer – perfect for packaging of fresh, processed or frozen meat, e.g. pork loin or pork neck, also with vegetables or in a sauce, marinade or spices.

Applications:

- Top and bottom films for thermoformers

- Films for flow-pack machines

- Lidding films for trays

- Bags / Pouches

Properties and available options:

- Temperature resistant from -40°C (-40°F) to 220°C (430°F)

- Microwavable – for defrosting and reheating

- Ovenable – according to label directions

- Great mechanical strength and formability

- Secure hermetic sealing guaranteed

- Low seal initiation temperature

- Excellent barrier properties with EVOH to optimize product shelf life

- Convenience of storage and transport, including storage in a home refrigerator

- Up to 10 colors can be printed for packaging presence enhancement

- Material consumption reduction, low carbon footprint

- High transparency and gloss

- Packing on standard machines

- Interlayer printing on the bottom film

- No need to double pack

- Top cover film, sealable to CPET trays

Benefits for the Consumer:

- Eliminates the need to process raw meat

- No contamination of the counter and ovenware

- Retains vitamins and minerals contained in the product

- Reduces the need to add large amounts of salt and spices

- Air circulation facilitates browning and preserves the taste and aroma of the food

- The packaging does not heat up – cool to the touch after removing from the oven

- Even heat distribution ensures a delicate and tender texture of the meat

- No need to prepare and clean up + Reduced cooking time = Saves time and energy

Share This Story, Choose Your Platform!

Leave A Comment

You must be logged in to post a comment.